This article explores the environmental and health challenges confronting Iraq’s brick industry, including child labor, hazardous working conditions, and severe environmental pollution. Harry Istepanian, emphasizes the urgent need to address the environmental and health challenges of the brick industry in Iraq to protect workers’ rights and mitigate the industry’s detrimental impact on public health and the environment

The brick kiln industry in Iraq has deep historical roots from the days of the Sumerians, c. 4100-1750 BCE. with traditional methods of brick production passed down through generations. Following the conflict-ridden years, Iraq embarked on extensive infrastructure rebuilding efforts, leading to a significant rise in demand for building materials. According to IC3+, the number of brick kilns in Iraq surged from 164 in 2000 to over 850 by 2023, as observed through satellite imagery. This surge propelled production from 7 million tons in 2000 to over 43 million tons in 2023. Many of these kilns continue to operate using outdated and labor-intensive methods.

Iraq’s brick industry largely relies on traditional tunnel-type kilns that use manual methods for molding and firing bricks. While there has been some adoption of newer technologies in recent years, heavy fuel oil (HFO) remains the predominant fuel source for firing these kilns. Despite its harmful effects on both human health and the environment, many kiln operators continue to rely on subsidized HFO. The brick industry in Iraq is subject to various regulations, but enforcement is often weak and many kilns operate outside the legal framework, continuing harmful practices with little oversight.

In 2020, a report by the Fiscal Auditing Bureau estimated that a single kiln consumes close to 1,400 tons of HFO annually. The Bureau also calculated that supplying fuel to each kiln costs around US$ 570,000, yet kiln owners pay only US$ 117,000 for the purchased fuel. This results in the government subsidizing fuel by more than 80% of the fuel costs annually.

The brick industry remains deeply entrenched in Iraq’s social and cultural fabric, employing thousands of workers, many from marginalized and impoverished segments of society, including women and children. These workers are primarily unskilled laborers who endure limited access to healthcare, education, and basic sanitation while working in harsh and unsafe conditions.

In Nehrawan, 70 km east of Baghdad, over 9,000, mainly women and children, work long hours, often exceeding 12 hours a day, for daily wages as low as 10,000 dinars (less than $8). They work in poorly ventilated and unsafe temporary shelters. According to the Baqubah Health Department, 11 workers were diagnosed with cancer in 2023, and 3 have died due to environmental conditions. In Nasiriyah, 350 km south of Baghdad, numerous deaths were documented including cases of breast cancer, asthma, pneumonia, and infertility among young people, along with deformities in newborns. Unions and NGOs have repeatedly called for environmental and labor rights reforms, emphasizing the urgent need for comprehensive changes within Iraq’s brick manufacturing industry. These reforms are critical not only to safeguard workers’ fundamental rights but also to mitigate the industry’s severe impact on public health and the environment.

Burning high sulfur HFO in the kilns is a major source of a range of harmful pollutants, including sulfur dioxide (SO2), carbon monoxide (CO), black carbon, carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM2.5), and heavy metals. These emissions significantly contribute to air pollution and have detrimental effects on both the environment and human health.

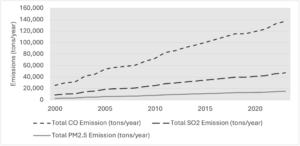

IC3+ estimates for every 1,000 bricks, there is an average emission of 6.35-12.3 kg of carbon monoxide (CO), 0.52-5.9 kg of sulfur dioxide (SO2), and 0.64-1.4 kg particulate matter (PM2.5). In 2023, IC3+ calculations showed that brick kilns in Iraq emitted an average of 137 thousand tons of CO, 47 thousand tons of SO2, and 15 thousand tons of PM2.5. These emissions contribute significantly to Iraq’s overall greenhouse gas emissions.

In a letter issued by the Ministry of Environment dated 2022 to the Iraqi Council of Representatives, the Ministry reported alarming levels of various pollutants emitted from brick kilns in the Nahrawan area. The measured CO ranged between 4.9 ppm to 37.3 ppm, significantly exceeding the maximum allowable by WHO of 9 ppm. This indicates a serious pollution issue with carbon monoxide levels far above the safe limit. Other measurements also exceeded the allowable levels reaching dangerous levels of toxicity including mercury, lead, chromium, cadmium, and arsenic have been the most common heavy metals found in the samples gathered from the area. Besides, severe human exposure to the most common heavy metals, the report highlighted severe air pollution and potential health risks in the area.

| Measured Value | Maximum Allowable Level | ||

| Low | High | ||

| Carbon Monoxide (CO) [ppm] | 4.9 | 37.3 | 9 |

| Nitrate Dioxide (NOx) [ppm] | 0.1 | 0.3 | 0.11 |

| Sulfur Dioxide (SOx) [ppm] | 0.05 | 0.01 | |

| Hydrogen Sulfide (H2S) [ppm] | 20.12 | 0.06 | |

| Total Suspended Particulates (TSP) [µg/m3] | 9801.7 | 150 | |

| Lead (Pb) [µg/m3] | 125.7 | 6.55 | 0.5 |

| Nickel (Ni) [µg/m3] | 133.9 | 0.002 | |

| Chromium (Cr) [µg/m3] | 1.15 | 3.55 | 0.002 |

Contamination of the soil and groundwater spans over 40 square kilometers within a 25-kilometer perimeter, affecting nearby villages and farms and contaminating crops. This environmental degradation poses significant health risks to local communities reliant on agriculture, highlighting the urgent need for remediation efforts and sustainable agricultural practices to mitigate further damage and restore the affected areas.

Satellite Imagery of Nahrawan Brick Factories (Google Earth)

Satellite Imagery of Nahrawan Brick Factories (Google Earth)

In April 2024, the Council of Ministers granted a three-year period for kiln owners to transition from burning HFO to using liquefied petroleum gas (LPG). This decision followed the Ministry of Oil’s November 2023 mandate requiring brick factories across Iraq to adopt LPG to reduce pollution. Many experts argue that the damage to soil and groundwater is already extensive and could take decades to fully remediate. The prolonged use of HFO has led to significant contamination, permeating the soil and groundwater and causing enduring ecological and health impacts. The situation is exacerbated by leachate in Nahrawan from a nearby landfill, further contaminating groundwater beyond repair. While the shift to cleaner fuel sources marks progress, the historical pollution from years of HFO use will require extensive efforts to mitigate its adverse effects on the environment and public health.

Photo courtesy of Iraq Observer (2023)

Photo courtesy of Iraq Observer (2023)

Addressing the environmental and health challenges of the brick industry in Iraq will require strict regulatory measures, technological investments, improved workers’ health and safety conditions, and the promotion of alternative materials to reduce environmental pollution caused by outdated production methods. Implementing these regulations can support Iraq in achieving sustainable development of the construction sector while safeguarding the well-being of its workforce and the broader community.

Harry Istepanian is a PMP certified, independent Chartered Engineer (CEng.) with more than 30 years of experience in large-scale power and water utility and IWPP projects in developing countries, including SE Asia and MENA in addition to New Zealand and Australia.

![Iraq Climate Change Center [IC3+]](https://iraqclimatechange.org/wp-content/uploads/2024/06/logo2.png)